Most Popular Product

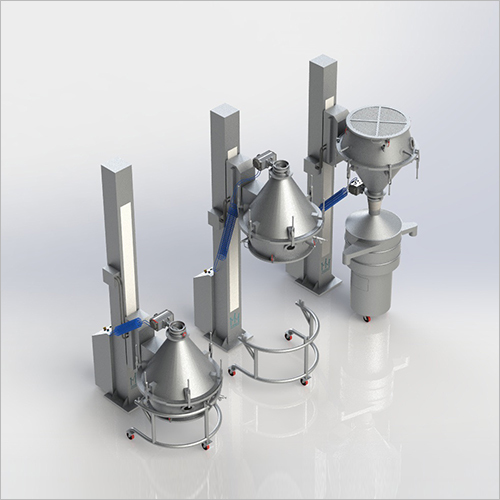

Double Cone Blender

350000 INR/Number

Product Details:

- Type Other

- Material Stainless Steel 316/316L

- Capacity 10-2500 Liter/day

- Computerized No

- Control Mode Automatic

- Voltage 220V - 440 V Volt (v)

- Weight (kg) 150 Approx. Kilograms (kg)

- Click to View more

X

Double Cone Blender Price And Quantity

- 1 Number

- 350000 INR/Number

Double Cone Blender Product Specifications

- Automatic

- Yes

- Other

- 150 Approx. Kilograms (kg)

- 220V - 440 V Volt (v)

- Silver

- No

- 10-2500 Liter/day

- Stainless Steel 316/316L

Double Cone Blender Trade Information

- MUMBAI

- Others

- 10 Number Per Month

- 4 Week

- WOODEN & Plastic Wrapping

- All India Pondicherry Uttarakhand Himachal Pradesh Jammu and Kashmir Arunachal Pradesh North India Goa Maharashtra Telangana Haryana Daman and Diu Bihar Nagaland Meghalaya Dadra and Nagar Haveli Gujarat West Bengal Andhra Pradesh Chandigarh Punjab South India Tamil Nadu Andaman and Nicobar Islands Madhya Pradesh Central India Lakshadweep Odisha Mizoram Assam West India Kerala Chhattisgarh East India Manipur Sikkim Delhi Uttar Pradesh Tripura Rajasthan Karnataka Jharkhand

- ISO & GMP

Product Description

The folding, spreading, and cascading action of the Mark Makers Conical Blender provides a rapid, homogeneous blending of dry and semi-dry materials. The end over end rev olving action, moving materials in and out of a restricted area results in a thorough intermeshing of the products into a uniform mix.Other Detail:-Range from Lab Model to Production Model (up to 4000 Itrs) based on the fill level of 55% of total volume. Each blender design is customized to suit the customer's specific requirements. For Improved Blend Uniformity Special designs incorporating internal deflector cones, or angled shell bodies are available upon request. Automated Drum Loading System Conical Blenders can be furnished with a PLC controlled, automated drum loading system. With one full rev olution of the blender, the entire contents of a product container (fibre, plastic or stainless steel drum) can be transferred into the blender and back into drums after mixing, in a dust-free operation. This system eliminates costly mezzanine platforms and other feed systems which require special docking mechanisms that create a risk of spillage. During loading. the operator simply rolls the drum onto the roller conveyor, raises the lift to squeeze the drum against the valve discharge flange seal, and initiates the read cycle. The blender slowly rotates one rev olution while automatically opening and closing the valve, and stopping at the zero position. The empty drum is lowered, and replaced with a full container to repeat the cycle until all contents are charged. During discharging, an empty drum is positioned on the roller conveyor and sealed against the valve discharge flange seal. The operator opens/closes the valve to fill the drum, lowers the drum, and replaces with an empty drum to repeat the cycle until all contents have been discharged.

Features:

- PLC controlled fully automatic load and discharge functions.

- Butterfly discharge valve is clamped to the blender outlet for quick disassembly and with Quick release design for ease of cleaning and maintenance. Valve flange seal can be customized to suit The customer's product container.

- 0 Degree position for discharge is provided

- Special PLC programming with safety interlocks for optimum operator safety. Shaft-mounted gear motor installed via shrink disc coupler eliminates maintenance of traditional gear drive. Speed

- regulation via AC variable frequency

PRODUCT RANGE :

R & d Range : 1 Ltrs to 25 Ltrs

Production Range : 25 Ltrs to 5000 Ltrs

Enter Buying Requirement Details

Other Products in 'Production Scale' category

|

MARK MAKER PHARMA ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |