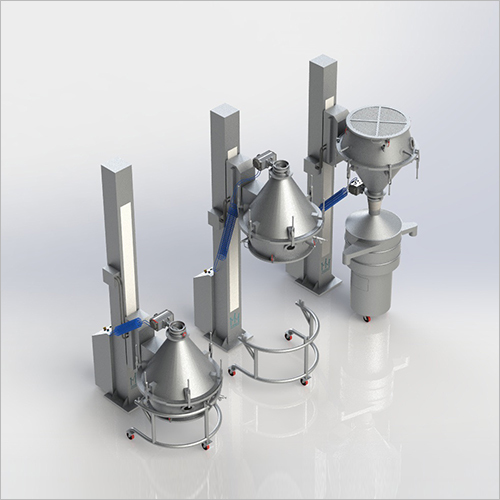

Fluidized Bed Equipment

Product Details:

- Type Other

- Material Product Contact SS 316 ; Non contact SS 304

- Capacity 5 to 500 kg Kg/hr

- Computerized Yes

- Control Mode Automatic

- Voltage 220 V - 415 V Volt (v)

- Power 10 to 100 Horsepower (HP)

- Click to View more

Fluidized Bed Equipment Price And Quantity

- 1250000 INR/Number

- 1 Number

Fluidized Bed Equipment Product Specifications

- 0.2 to 4 Tonne

- 220 V - 415 V Volt (v)

- Matte Grey

- Automatic

- Product Contact SS 316 ; Non contact SS 304

- Yes

- 10 to 100 Horsepower (HP)

- Other

- 5 to 500 kg Kg/hr

Fluidized Bed Equipment Trade Information

- Palghar

- 1 Number Per Month

- 8 Week

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- CE, ATEX, GMP

Product Description

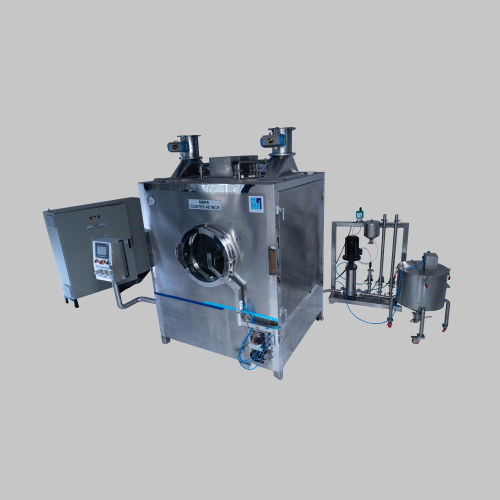

Fluid Bed Dryerworks on the principle ofcreating a fluid turbulence in granulated or wet powder produced by means ofhot air flowing in an upward direction and drying the product to the desiredtemperature

Wet granules are completely fluidized by a powerful steamor electrically heated air thereby achieving high heat transfer rate anduniform temperature across the product

Unique design of perforated plate for uniform dryingwithout any racking process

In the pharmaceutical industry this innovative methodhas replaced the timeconsuming tray drying long ago In addition fluidizedbed drying provides controlled and uniform drying conditions compared to theuneven drying in trays

Salient Features

MMPE Fluidized Bed Equipmentprovides you with theflexibility to use a system tailored to your specific process requirements

ProcessingCapacity 50 100 of total volume

FluidBed Bottom Spray Pellet Particle Coating WURSTER

TopSpray Granulation

PowderPellet Drying

Other Detail

cGMP Model

Electrical or Steam Heating

Three Stage Filtration ie 20 microns EU3 5micronsEU5 03 microns EU13

Precise temperature control ie 1c

PLC controlled

Certified Explosion relief flap

Flameproof construction Positive earthling device

Intelligent process control and safety interlock by PLC Colour Touch Screen MMI along with printing

21 CFR part11 and SCADA compatibility

Validation support including DQ IQ OQ documents

Pharma grade finger bag

Product Range

R D Model 1 Kg 5 Kg 10 Kg 15 Kg

Production Model 30 Kg 60 Kg 120 Kg 200Kg 250 Kg

300 Kg 500 Kg

Other Products in 'Production Scale' category

|

MARK MAKER PHARMA ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |