Most Popular Product

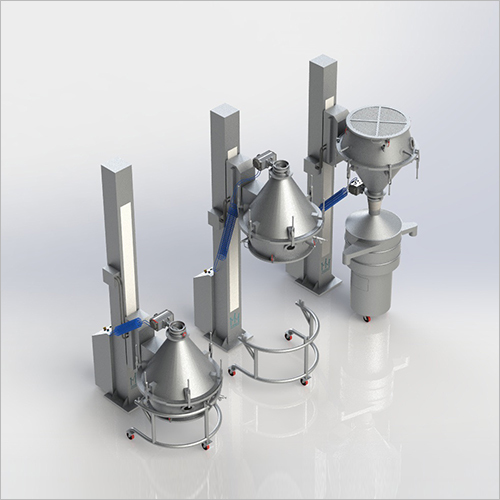

Vibro Sifter

120000 INR/Number

Product Details:

- Type Other

- Material Stainless Steel 316/316L

- Capacity 10 Kg - 500 Kg Kg/hr

- Computerized No

- Control Mode Automatic

- Voltage 220V - 440 V Volt (v)

- Weight (kg) 150 Approx. Kilograms (kg)

- Click to View more

X

Vibro Sifter Price And Quantity

- 120000 INR/Number

- 1 Number

Vibro Sifter Product Specifications

- 1 Year

- 10 Kg - 500 Kg Kg/hr

- Automatic

- Stainless Steel 316/316L

- Silver

- No

- 150 Approx. Kilograms (kg)

- Other

- 220V - 440 V Volt (v)

Vibro Sifter Trade Information

- MUMBAI

- Others

- 4 Week

- Wooden / Plastic Wrapping

- Asia Western Europe

- All India

Product Description

MMPE Vibro Sifter works on gyro principle The required gyratory motion is obtained from specially designed gyro motor which is fitted underneath the vibrating assembly The complete vibrating assembly is isolated from the base by means of specially designed rugged springs This is accomplished by vibrating the screens in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaft The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the periphery The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern Thus the material moves across the screens and also in the vertical and tangential planes enabling maximum screening The sifter unit consists of Specially designed vibratory motor to run on 400 440V suitable HP 3 phase 50 cycles electric supply with adjustable eccentric weights at the top and bottom of the motor shafts mounted vertically at the center of the base plate of screening unit Screening unit consists of SS 316 screen sandwiched between SS 316 hopper and bowl with the help of special clamp gasket This in turn is clamped to the base plate Rugged Springs placed over the circular motor base amplify the vibration and at the same time restrict the vibration from being transferred to the floor

Other Detail

- Noiseless Maintenance free high speeds

- Available in various models providing screening diameter of 12 20 30 36 48 60 etc

- Portable and compact Electric power requirement less than another machine of the kind in the industries lower energy Consumption compared to the reciprocating vibratory system

- Standard machine is with TEFC motor ex plosion proofflame proof motor material

- All contact parts and screen of SS 316 AISI stainless steel material

- Easy dismantling and cleaning facility for contact parts

- A wide range of screen sizes 4300 Mesh Double Triple deck screens with outlet and hopper for bottom deck available on request

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Production Scale' category

|

MARK MAKER PHARMA ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |