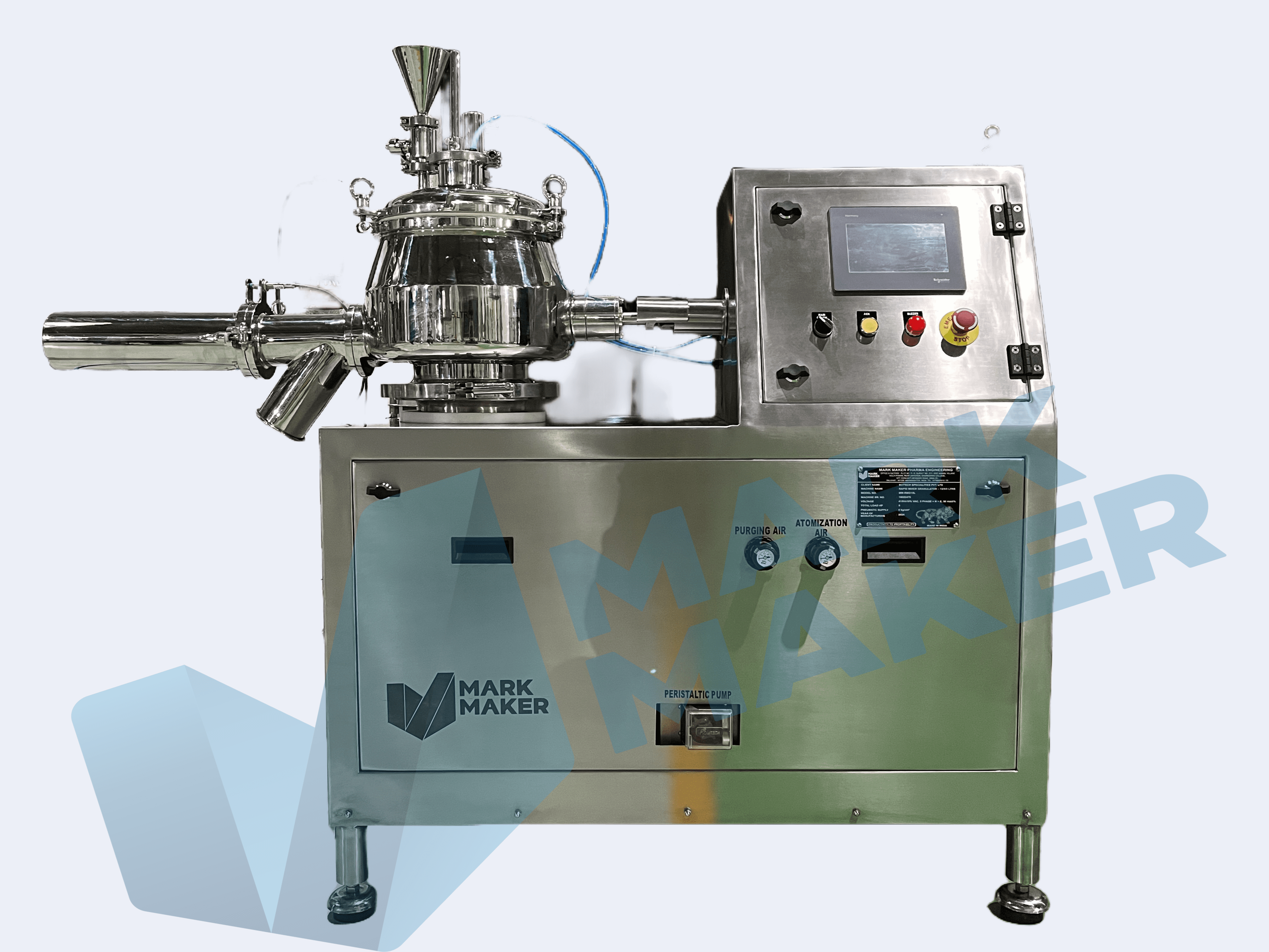

Rapid Mixer Granulation

Product Details:

- Type Other

- Material Product Contact SS 316 ; Non contact SS 304

- Capacity 2 to 1250 Litres Liter/day

- Computerized Yes

- Control Mode Automatic

- Voltage 220 V - 415 V Volt (v)

- Power 4 to 135 Horsepower (HP)

- Click to View more

Rapid Mixer Granulation Price And Quantity

- 1 Number

- 700000.00 - 9500000.00 INR/Number

- 700000 INR/Number

Rapid Mixer Granulation Product Specifications

- 2 to 1250 Litres Liter/day

- Yes

- 100 to 3000 Kilograms (kg)

- Other

- 220 V - 415 V Volt (v)

- 4 to 135 Horsepower (HP)

- Product Contact SS 316 ; Non contact SS 304

- Matte Grey

- 1 year

- Automatic

Rapid Mixer Granulation Trade Information

- Palghar

- Others

- 1 Number Per Month

- 6 Week

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

- GMP, CE, ATEX.

Product Description

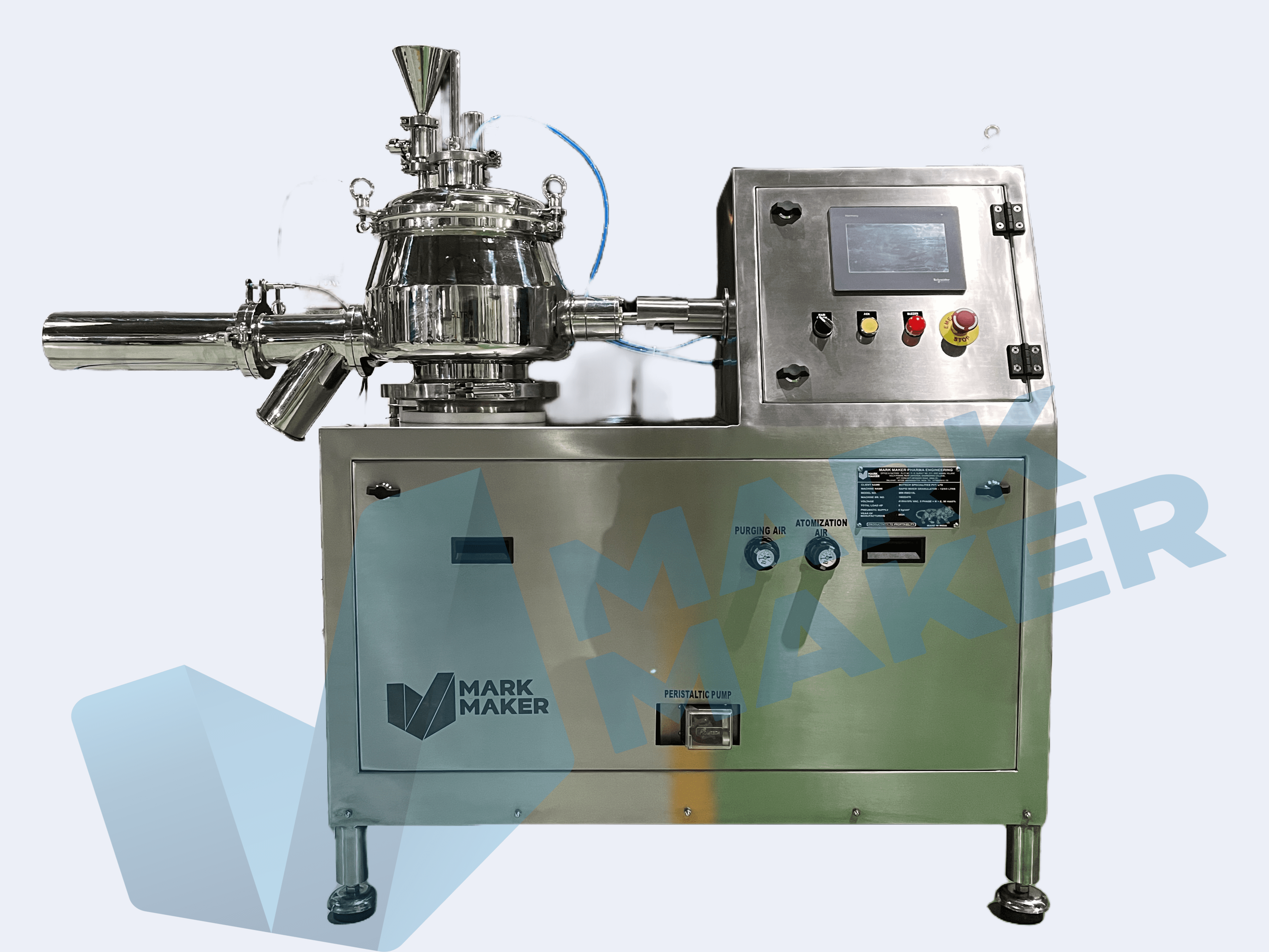

Taking quality as our principal concern, we are betrothed in presenting an excellent quality of Rapid Mixer Granulator.Product Description:RAPID MIXER- High Shear Mixer Granulator has been developed for mixing of ingredients as well as wet granulation required for tablet/capsule manufacturing. This is achieved by reduced processing time, more homogeneous mixing, uniformity of Granule size and above all maintaining improved hygiene compliant to cGMP norms.

The Mixing Bowl :It is circular with a large diameter and flat base. The top portion of the bowl is conical shape to assist mixing of cohesive powders. Constructed from SS316/316L.

The mixing bowl has an impeller for mixing the powders uniformly and a chopper for breaking the lumps formed during WET GRANULATION.

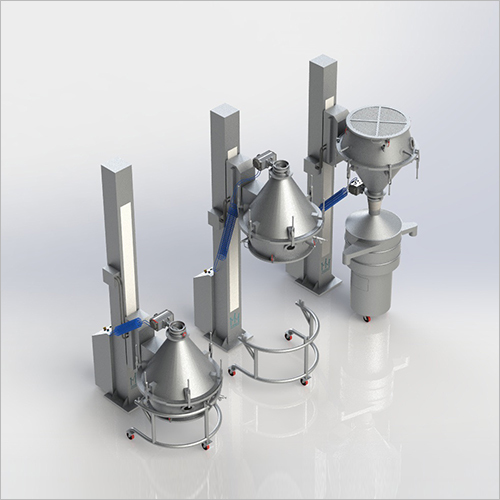

Online Co-mill:

MMPE RMG has a special optional feature for sizing of wet granules in line before drying in FBD.

The on line co-mill is provided on the discharge port to reduce the oversized lumps, resulting in reduced drying time by approximately 20%. As the lumps are small the product can be uniformly dried at lower temperature.

Product Range :

Lab Models : 2 Ltrs, 3 Ltrs, 5 Ltrs, 10 Ltrs.

Pilot Model : 15 Ltrs, 25 Ltrs

Production Model : 50 Ltrs, 100 Ltrs, 150 Ltrs, 250 Ltrs,

400 Ltrs, 600 Ltrs, 800 Ltrs, 1000 Ltrs, 1250 Ltrs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Production Scale' category

|

MARK MAKER PHARMA ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |